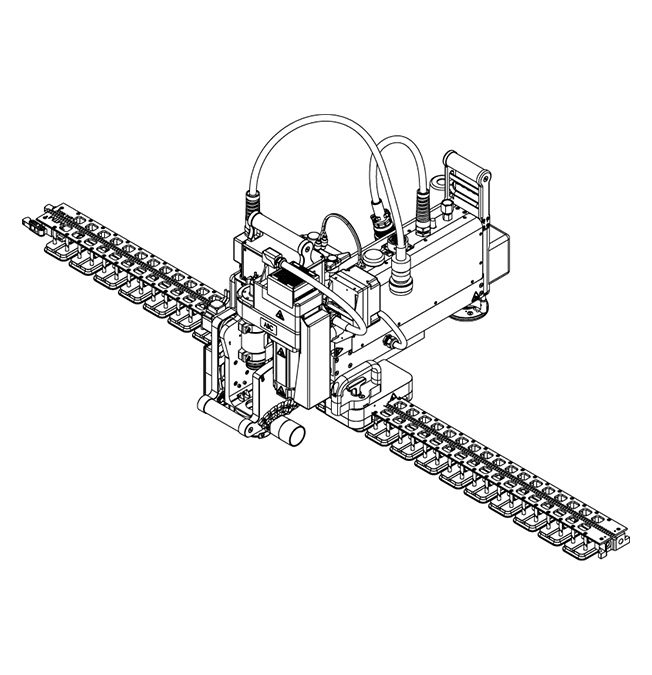

Mini Flextrack 1.0

A single rail double curvature capable system with A and B Axis travel and unlimited X-axis travel when linking vacuum rails around a fuselage. Y-axis travel extends 6”/152mm from edge of rail.

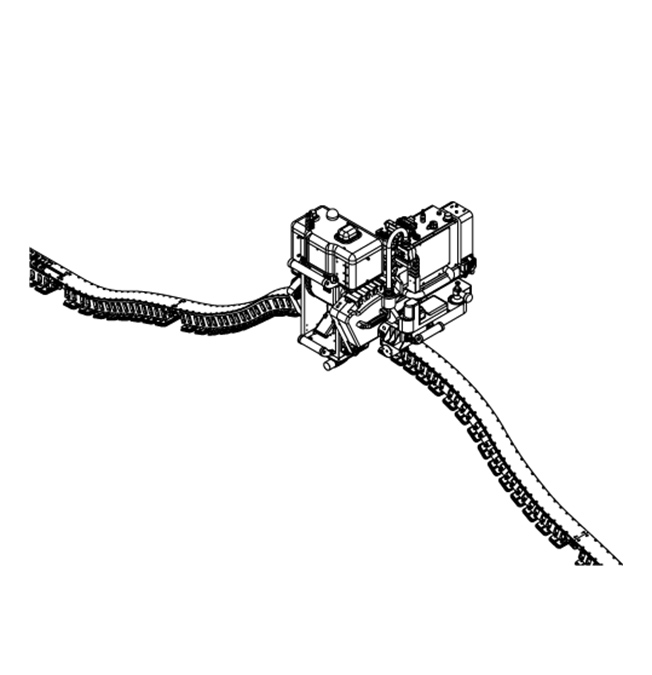

Mini Flextrack 2.0

A single rail double curvature capable system with A and B axis travel but a tighter radius along the X-axis than the Mini Flextrack 1.0. Rails can be linked for unlimited X-axis travel on fuselages and a B-Axis range of 18 degree motion exists to maintain normality to applied surfaces. Y-axis travel extends 16”/410 mm from edge of rail.

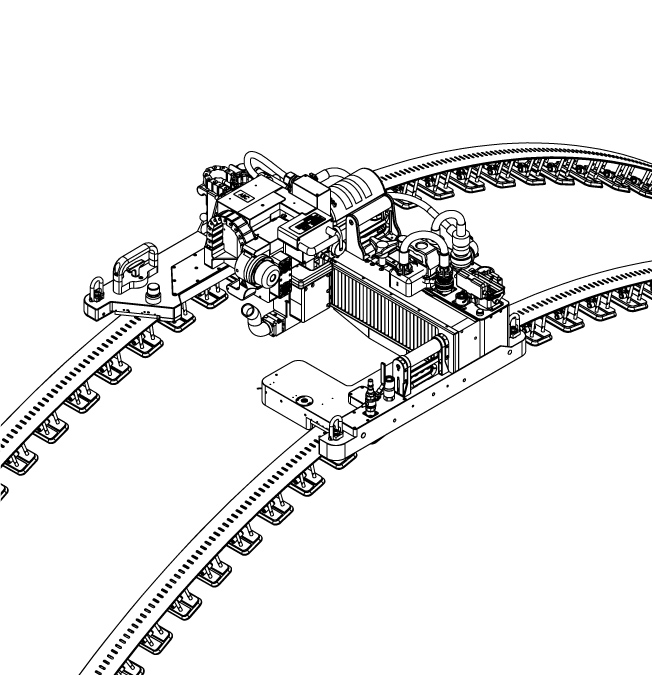

Light Flextrack 2.8

This double rail system utilizes MTM’s custom Mini Smart Drill End Effector. (The LFT 2.7.3 version utilizes the same double rail system but with a 3rd party end effector.) Capacity for unlimited X-axis travel when linking vacuum rails around a fuselage. The X-axis surface radius extends to 6.2ft/1.9m. Y-axis travel extends 47”/1200 mm from rail to rail.

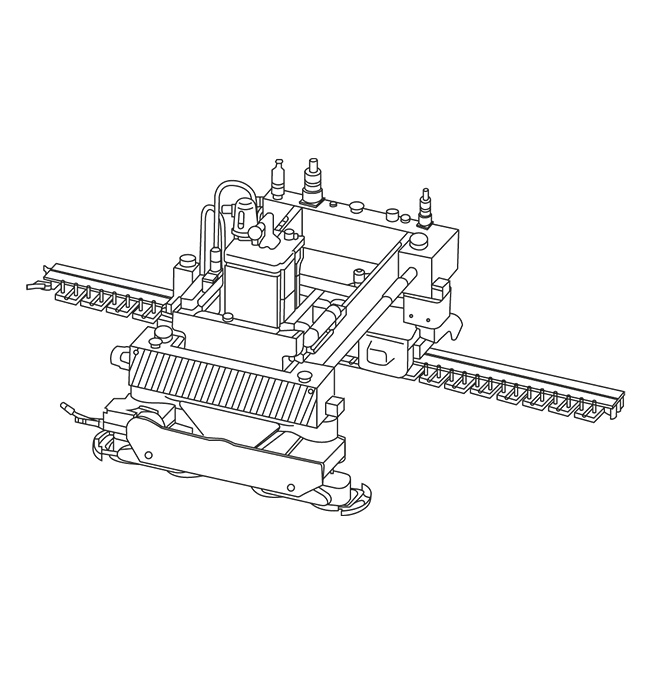

Light Flextrack 3.0

Single rail with crawler replacing 2nd rail. Unlimited X-axis travel using linked vacuum rails. The X-axis surface radius extends 5.9ft/1.8m. The A-axis motion is 5 degrees and B-axis motion is 15 degrees for normalization to surface. Y-axis travel extends 21.5”/550 mm from rail to rail.